Aerospace industry entry situation

Because there is an engine parts factory of IHI Corporation in Fukushima (Soma City), a number of companies which possess manufacturing or processing technologies for related parts are also located here. In addition, including engine parts in the aerospace field, achieving companies in space related equipment manufacturing such as rocket related parts, space satellites communications related parts, and companies which possess technologies or products that enable them to enter the aerospace related industry are located.

Aerospace industry entry situation

Achieving companies in the prefecture

(according to Fukushima Technology Centre)

- Aviation 41companies

- Space 37companies

(as of February 2022)

The shipment values of parts, mounting brackets and attachments for aircraft engines

No.2 in Japan

| Ranking | Prefecture | Shipping value (million yen) |

|---|---|---|

| 1 | Tokyo | 408,662 |

| 2 | Fukushima | 218,944 |

| 3 | Hyogo | 211,761 |

| 4 | Hiroshima | 94,060 |

| Total for Japan | 1,079,588 | |

Source: METI "Census of Manufacture 2020"

Challenges and contributions to "Hayabusa 2"

Many of the businesses located in Fukushima were involved in the manufacturing of the Hayabusa 2 which returned from its mission of collecting samples from an asteroid on December 6, 2020, in which the "Made in Fukushima" technology played a significant role.

Companies in the prefecture involved in "Hayabusa 2"

| Company Name (location) | Responsibility |

|---|---|

| NEC Platforms, Ltd. (Fukushima City) | Design and assembly of power unit for communication equipment |

| Furukawa Battery Co., Ltd. (Iwaki City) | Lithium Ion batteries for the asteroid probes |

| Fujikura Parachute Co., Ltd. (Tamura City) | Parachute for collecting capsule |

| Nippon Koki Co., Ltd. (Nishigo Village) | Cone shape propellant for the impactor |

| Tosei EB Tohoku Company Ltd. (Koriyama City) | Electron-beam welding for the impactor |

| Ishikawa Factory (Kagamiishi Town) | Production of container and cupper plate for the impactor |

| Tamatech Co., Ltd. (Kagamiishi Town) | Production of container and cupper plate for the impactor |

| Public University Corporation, University of Aizu (Aizuwakamatsu City) | Monitoring of near-infrared spectroscopy |

Transaction expansion support

Exhibition participation support

Promoting the technological strengths of the businesses in Fukushima, we support businesses to participate in exhibitions and business meetings outside the prefecture.

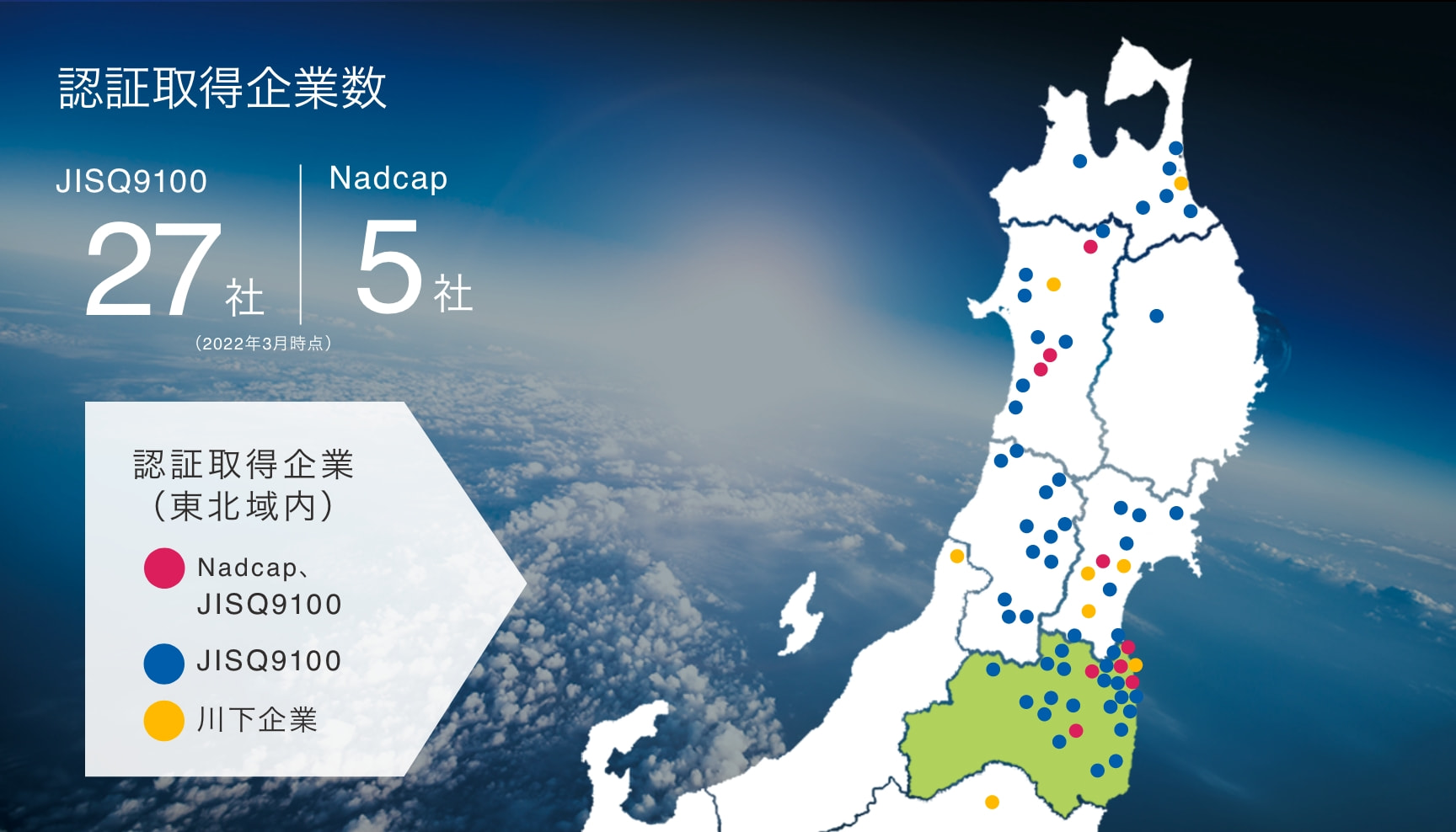

Certification acquisition support

Expert dispatch support

Working towards acquiring JISQ9100 and Nadcap certifications, we organize individual visits and training by consultants with experience in the aerospace-related industry.

Multi-faceted support

Acquisition, renewal, and maintenance of certification, introduction of new equipment,support for human resource development

We provide subsidies up to two-thirds of expenses for businesses in Fukushima to obtain certifications and participate in international exhibitions in order to enter the aerospace-related industry.

Initiatives for development of human resources

Installation of high-level advanced equipment

X ray CT devices, a 5-axis processing system for aircrafts, and non-destructive inspection machines have been introduced in the Fukushima Technology Centre. This equipment is used to produce prototypes for expanding business, and for training at professional organizations, etc. to support the technical capabilities of companies.

High-level advanced equipment training

Training for technology required in the manufacturing of aircraft parts is conducted and human resources are cultivated for aerospace-related industries utilizing resources such as the 5-axis machining system for aircraft, non-destructive inspection machines, and composite materials testing equipment adopted by the Fukushima Technology Center.

- 5-axis machining training

- Non-destructive test technician education and training (penetrant testing)

- CAD/CAM operation training

INDEXGet to know Fukushima

03Challenge